On-Line Pipe Wrapping

REINFORCEKIT® 4D (R4D) is a wet lay-up repair system, wrapped around the pipe to reinforce the damaged area, restore original pipe integrity and prevent further deterioration.

This composite technology, made of Kevlar® tape and bi-component epoxy resin, is a great alternative to metal clamp, welded sleeve and pipe replacement.

3X ENGINEERING (3X) developed its own software to design the repair and define the material requirements according to ISO 24.817 and ASME PCC-2 standards.

Onshore / Offshore Topside

Implementation steps

Uses

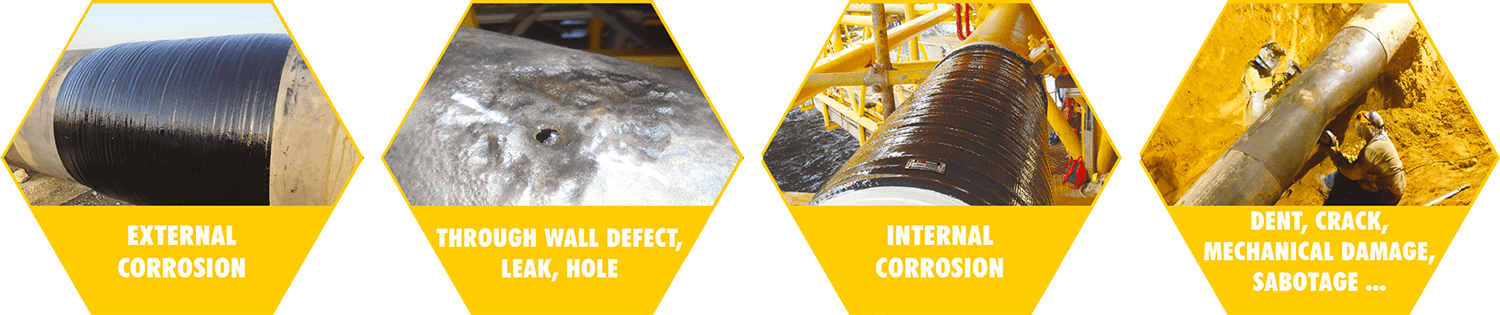

- Reinforce pipe suffering from:

– internal and external corrosion

– pinhole, leakage, crack

– mechanical damage, dent

– severe abrasion, erosion

– sabotage - Restore pipe integrity

Application

- Onshore and offshore (topside)

- All pipe geometries including welds, elbows and tees

- All pipe sizes (no limitation)

- High pressure pipeline

- Pipe operating from -50°C up to +400°C

- Pipe transporting most common fluid and gas

Benefits

- Online repair (no shutdown required except in case of leakage)

- No loss of production

- Non-conductive repair

- No hot work

- Long-term performance (up to 20-year lifetime)

Industry Applications

Oil and Gas

Petrochemicals

Offshore

Power Generation

Why Choose Us

Good Reputation

We have more than 20 years of experience with a good reputation in regards to quality, response time and commitment.

Safety Record

We have a trail of safety records.

Reliable

We hold reputable track records in the industry.

Quality

We are consistent with our quality of products.

Gallery

Ensuring Operational Integrity: In-Situ’s On-Line Pipe Wrapping Solutions

Safeguard your industrial processes with precision through our On-Line Pipe Wrapping Solutions. Contact In-Situ Group of Companies for tailored solutions that prioritize the longevity and reliability of your critical infrastructure.