In-Situ Group of Companies pioneers innovative On-Line Leak Sealing solutions, offering a temporary and customized fix for process system leaks without disrupting production. Our cutting-edge technology addresses a wide range of substances, including steam, water, air, oil, hydrocarbons, and chemicals, with a remarkable pressure rating up to 380 bar and a temperature range spanning cryogenic to 600°C. In the face of serious pipeline leaks, our approach stands as a preferable alternative to conventional shutdowns, allowing repairs while the system operates at full pressure and temperature. Leaks at flanges, straight pipes, elbows, tees, and valve glands are expertly handled by our experienced engineers and technicians, who understand the challenges posed by turbulent flow, corrosion, and erosion. Formerly known as In-Situ, In-Situ Group of Companies is committed to delivering cost-effective and reliable leak repair solutions promptly, ensuring a swift response to pipe, valve, or flange leaks and preventing costly unscheduled maintenance downtime.

On-Line Leak Sealing

On-line engineering solution for stopping almost any types of leaking under pressure without shutting down the production system.

Transforming Industry Challenges with On-Line Leak Sealing

Why Choose Us

Good Reputation

We have more than 20 years of experience with a good reputation in regards to quality, response time and commitment.

Safety Record

We have a trail of safety records.

Reliable

We hold reputable track records in the industry.

Quality

We are consistent with our quality of products.

Application

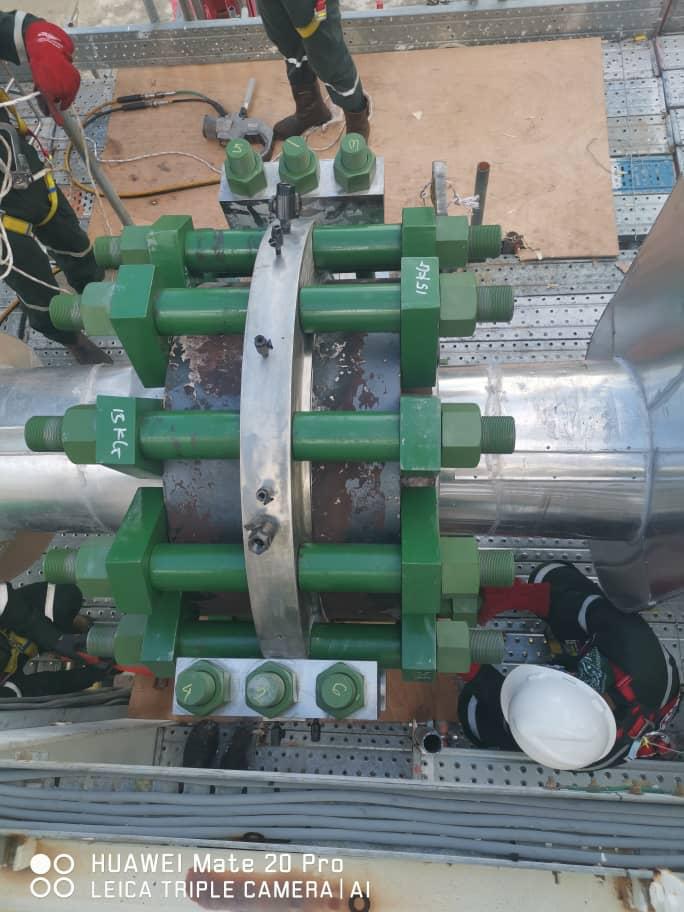

- Piping flange joint leaks.

- Equipment flange joint leaks eg. heat exchanger flange leaks.

- Valve bonnet, gland packing, pressure seal ring or body pinhole leaks.

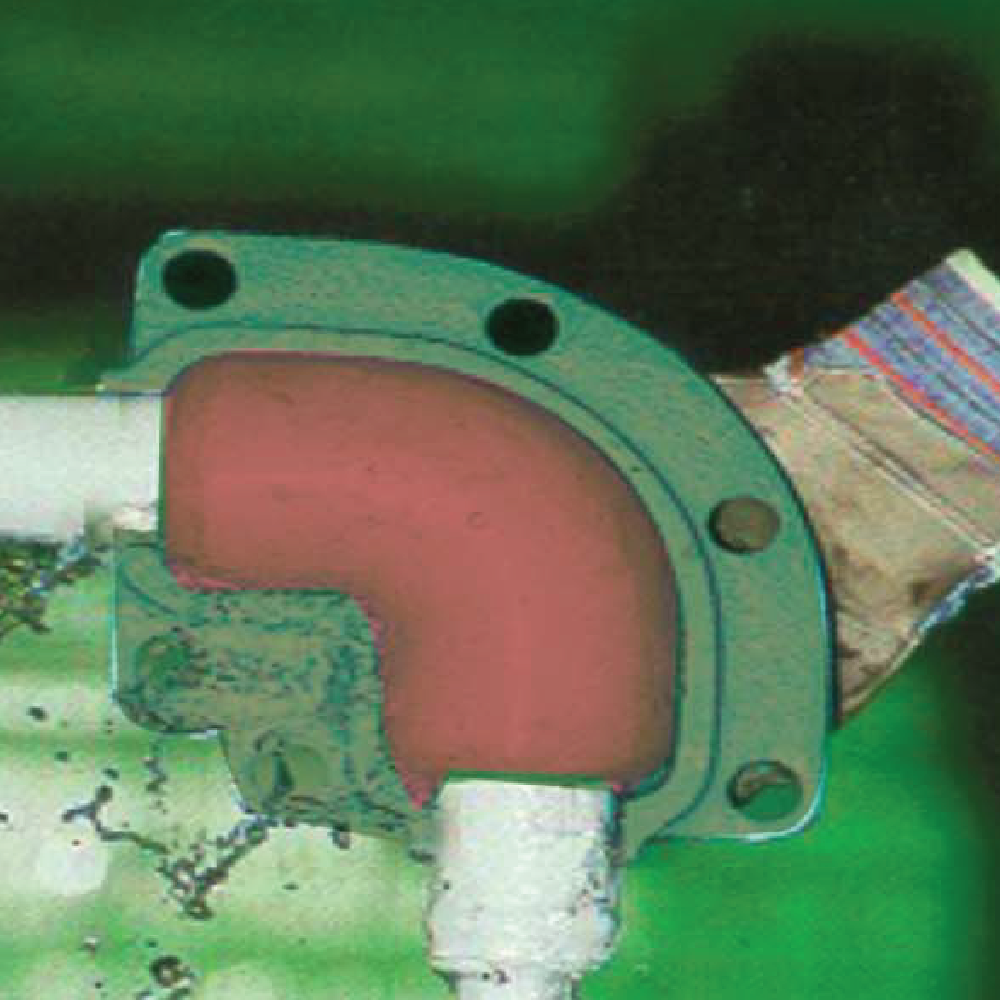

- Pipe joint leaks like elbow, tee, straight pipe, reducer, etc.

- All types of welding failure that leads to leaks eg. pinhole, cracks, etc.

- Casing pinhole, thinning pipe, etc.

Benefits of On-Line Leak Sealing

- Can stop leaks while plant continues operations.

- Reduces downtime – the client does not have to shut down or isolate the affected line.

- Avoids plant shut down that causes loss of production.

- Saves time and money.

- Increases plant safety.

- Environmentally friendly.

Industry Applications

Oil and Gas

Petrochemicals

Offshore

Power Generation

On-Line Leak Sealing

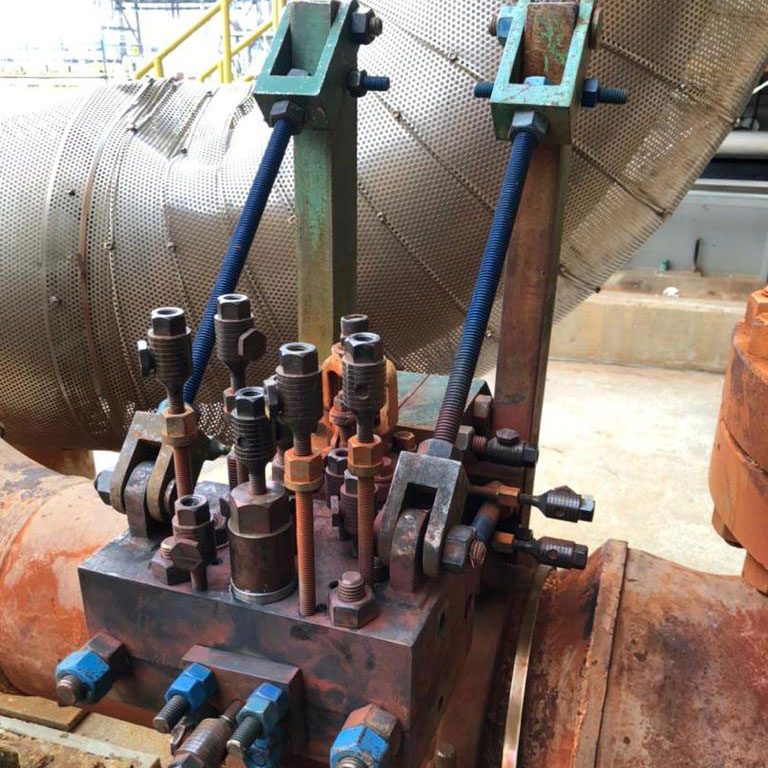

Elbow Leak

Flange Leak

Valve Gland Packing Leak

Sealed with Box Clamp

Sealed with Insert Clamp

Sealed with Drill and Tap

Gallery

Ensuring Operational Integrity: In-Situ’s On-Line Leak Sealing Solutions

Safeguard your industrial processes with precision through our On-Line Leak Sealing Solutions. Contact In-Situ Group of Companies for tailored solutions that prioritize the longevity and reliability of your critical infrastructure.