CTI Industries is a service company base in Orange, CT USA specializes in the restoration of condensers and heat exchangers since 1976. CTI developed a tub repair technique that till today is recognized as the most widely used cost-effective system in the world.

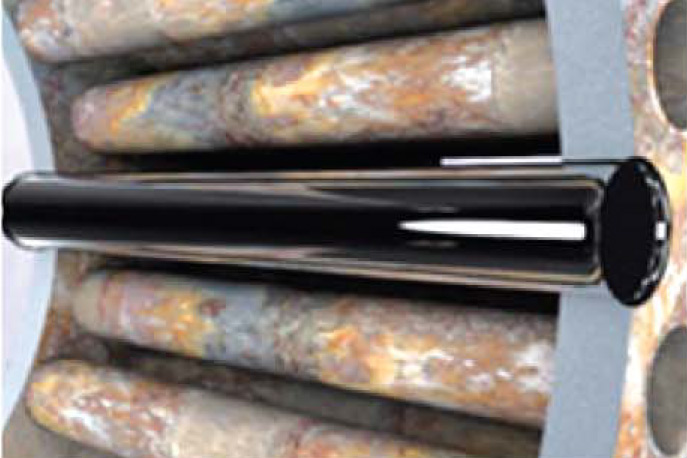

Common tube failures:-

- Tube-end erosion/corrosion

- Stress corrosion cracking

- Crevice corrosion

- Localized pitting

- Ammonia grooving

- Reinforced tube-to-tube sheet joints